Complex offshore Transport & Installation project for huge gas platform Aasta Hansteen

More than two years of preparations will be needed for a unique catamaran float-over operation that is due for completion in a period of just six weeks in late 2016. More than fifty Dockwise colleagues are hard at work on complex calculations for the transportation and installation of the enormous gas platform Aasta Hansteen in Norway. Senior project manager Bas Polkamp elaborates on the plans.

Bas Polkamp — senior project manager

Unimaginable forces

Bas: “Our track record was important when it came to acquiring this project: we have prepared similar catamaran operations, albeit on a smaller scale. The Aasta Hansteen gas platform, which we will be installing on behalf of the Korean company Hyundai Heavy Industries (HHI) for the owner Statoil is absolutely gigantic. The topside alone weighs 25,000 tons. So moving and installing it involves almost unimaginable forces. During installation, the sea state, currents, wind and waves are major factors and calculating all these elements requires a lot of preparation time. It’s a project of extremes in every respect: the ultimate location is above the polar circle in very deep water and we are working with incredibly large structures.”

Transportation and Installation

“The Dockwise core activity involves moving large production platforms or floating structures, deploying our fleet of submersible transport vessels. We also install large topside facilities on fixed jackets,” explains Bas. “These are large steel structures that are installed on the seabed. On the top, there are supports for the topside. Positioning the topside generally involves sailing between the sides of the jacket, submerging the ship at exactly the right place and lowering the topside onto the jacket. Because of the specific design, our activities for the Aasta Hansteen require a large number of extra procedures.”

Three phases

The Aasta Hansteen is a SPAR (single point anchor reservoir). The lower part is the hull, or SPAR substructure, and the other part is the SPAR topside. “The Aasta Hansteen project consists of three phases,” continues Bas. “The first involves the horizontal transport of the hull, an enormous cylindrical buoy (diameter 50 meters, length 198 meters and weight 47,000MT) that we will take from the yard in Korea to a fjord near Stavanger in Norway in early 2016 using our largest vessel, the Dockwise Vanguard. In Norway, the hull will be moved upright and submerged by another contractor, and installed in an anchor spread (an arrangement consisting of large anchors and anchor chains to keep the hull in place) so that it is fixed firmly to the seabed. The hull is then ready to accommodate the topside. At that point, a sort of enormous barrel fifty meters across can be seen emerging from the waves. Then the second phase starts: transporting the topside, which is also being built in Korea. That operation will be carried out with our new ship, the White Marlin, which is similar in size to the second-largest Dockwise vessel, the Blue Marlin. The third phase will start in early 2016: the installation of the topside on the hull.”

Catamaran

“Given the fact that we cannot sail our ship over the hull, an alternative approach has been designed for the installation of the topside,” explains Bas. “We will be using two of our S-class vessels, the smallest in the Dockwise fleet. Large steel structures known as nodes will be mounted on the topside in Korea. Once the White Marlin has arrived in Norway with the topside, the two S-class vessels will maneuver alongside. At that point, they will already have been fitted out with four enormous support structures for the nodes. The supports include leg mating units, large steel compartments covered with thick layers of rubber. The leg mating units are designed and manufactured by our subsidiary, Offshore Kinematics Inc. (OKI) in Houston. They can be tailored precisely to manage the weight of the topside and the prevailing dynamic of wind, weather, waves and currents. Once the two ships have been positioned on either side of the White Marlin, they are raised and the White Marlin drops down and sails out. The result is a sort of catamaran structure with the topside linking the two hulls. Then we deploy a number of tugs to move the topside into position above the SPAR hull and couple them together.”

The fact that we have a unique ship like the Dockwise Vanguard certainly helped us to win the contract

Pre-phase

Bas explains the pre-phase: “After the engineering department at Statoil had studied the feasibility of the initial concepts, they called in the specialist design company CB&I to conduct the pre-FEED and FEED (front-end engineering design) studies and the risk analysis, and to draw up the financial estimates. On that basis, CB&I advised a particular approach. Then a range of parties were invited to tender for the project. In the tender phase, we worked up the data from the study into method statements that eventually served as the basis for the acquisition of the project. We worked for more than eight months with a team of five or six people on the tender for this project. The fact that we have a unique ship like the Dockwise Vanguard certainly helped us to win the contract.”

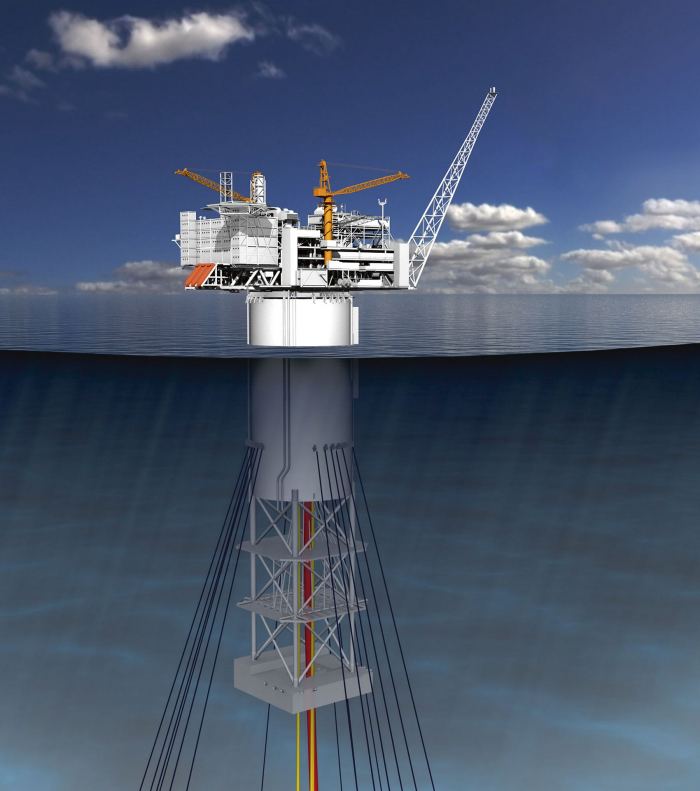

Artist’s impression. The entire structure — the upper and lower parts — make up the SPAR. The lower part is the SPAR hull — the upper part is the SPAR topside

Follow-up

“On the basis of our method statements, we moved onto the concept phase, which involved intensive consultations with the client. The next step was to work out all the details of the concept, which means planning the operation right down to the nuts and bolts level. That is the phase we are in at the moment. The next step will be to make all the practical preparations for the operational phase,” says Bas, who goes on to describe the current state of play: “We currently have about fifteen colleagues working constantly on this project at our Dutch office, and we have about another thirty colleagues working full-time at our offices in Shanghai and Houston. A large part of their work consists of structural engineering. That involves making calculations for the support structures and for the skidding operation to move the topside onto the vessel in an operation that involves the topside sliding slowly onto the ship, which really does mean ‘steel on steel’. Calculating the forces generated is an intensive job for our engineers. In order to keep a grip on the coordination of all the individual calculations right down to the extremely detailed level, a range of quality controls have been set up. We safeguard quality by getting our engineers and even different departments to check each other’s work” explains Bas.

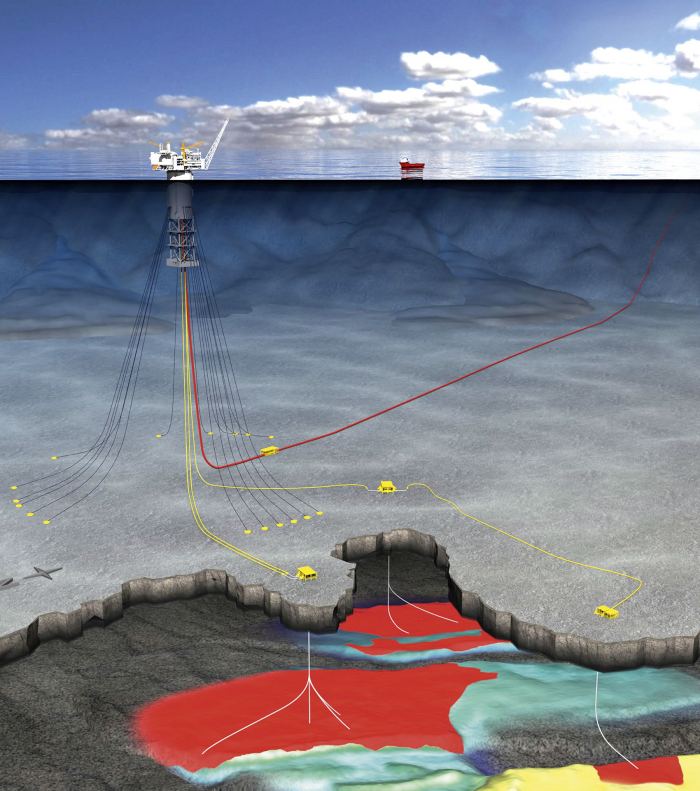

Artist’s impression. Impression of the Aasta Hansteen gas platform in operation

Synergy

“In addition, lots of other disciplines are working on keeping all the different aspects of the assignment on track. Our marine engineers focus on the hydrodynamics: they make calculations of the ship behavior, the behavior of the floating cargo, and the impact of the wind, currents and waves. And we have construction draftsmen getting all the ideas and calculations onto paper; transport engineers make the stability calculations and the ballast calculations, and we also have cost controllers, project planners, fleet technicians, HSES engineers, QAQC engineers, cost estimators, legal counsels, contract engineers, logistics engineers, commercial and procurement officers working on all the aspects that play a role in this enormous project.”

We have been involved in engineering work on this project for more than two years

The Aasta Hansteen project will also generate work for other Boskalis units. “Together, we have a wide spectrum of services and, of course, we make the most of that on this project, too,” smiles Bas.