Majestic new vessels, a truly international team, new offices in Aberdeen and Dubai, impressive high tech equipment and an increasing number of challenging assignments: Boskalis Subsea Services is going through a period of strong development. What subsea activities do they perform for clients? What are the main challenges involved? Regional director Bert van der Velden takes us behind the scenes.

Boskalis Subsea Services has many years of experience in air diving and saturation diving (SAT). “We have built an impressive track record in Europe, West Africa and the Middle East,” says Bert van der Velden, who is responsible for the Subsea Services organization in the Netherlands and Dubai. “At one time we carried out a lot of maintenance works according to the exact instructions of the client. However, the oil and gas industry is developing all the time and projects are getting more complex and demanding. Nowadays, we focus more on assignments which allow us to take on more responsibility, for example to carry out the engineering or fabrication tasks, and as such unburden the client.”

New vessels

To perform these tasks Boskalis Subsea Services has an impressive fleet of high tech diving support vessels (DSVs), a broad selection of diving equipment and Remote Operated Vehicles (ROVs). “The DSV Constructor is working full time in the Middle East. Our ‘air’ DSV Protea has been working all year round on the North Sea for the last ten years. Our latest additions are our high-end DSVs BOKA Da Vinci and BOKA Atlantis. The new DSVs set us apart in the higher segment of the market, allowing us to expand our field of work to the northern part of the North Sea, where the water depths and rough weather conditions make the work more challenging and complex,” says Bert. “Much of the offshore work in this area is managed out of Aberdeen, the epicenter of the European offshore sector. We have substantially expanded our Subsea organization in Aberdeen to ensure we have a clear presence and good visibility in the major league of the subsea world. But we also have a solid organization in the Netherlands and Dubai, which allows us to be close to our clients in different areas of the world.”

Subsea infrastructure

What is the underlying necessity of your work?

“The media tend to use the same sort of images to accompany stories about the offshore oil and gas industry: fixed and floating platforms rising out above the water surface. In itself this makes sense because platforms are one of the few visible aspects of the exploration and production process. But the most essential bit takes place under water and is therefore invisible. In almost all the world’s oceans the seabed is crisscrossed with a tangle of thousands of kilometers of pipelines, hundreds of distribution stations, manifolds, hydraulic controls, electrical control systems and pumps. This complex subsea infrastructure is installed and eventually removed according to strict environmental and safety standards. In the meantime all this infrastructure has to be maintained. Just like technical installations above water it has to be inspected and tested regularly and repaired when necessary. A shore based technical team can simply hop in a van to drive to a maintenance job, but we carry out that kind of work under water using divers, or state-of-the-art Remotely Operated Vehicles (ROVs), which require our specialist vessels to sail out from port to open sea, sometimes with more than one hundred people onboard to support just 1 or 2 divers in the water.”

Working under pressure

How would you describe the work of a commercial diver? Are there similarities to recreational diving?

“No, our work is nothing like tropical scuba diving in crystal-clear waters. For our commercial divers ultimately diving is a means of travel to get to a worksite which happens to be in the water or on the seabed. The diving industry attracts a wide variety of people from diverse cultural and professional backgrounds. Entrants to the industry range from the ex-military, university graduates, people who have had a first career, trade apprentices and professionals, to those who have been sports divers and simply enjoy diving. The actual work to be done when you get to the jobsite can be incredibly varied including underwater cutting, installing bolts and nuts or even structures using vessel-based cranes, supporting drilling rigs, or visual inspection of a weld, or simply taking a photograph. Whatever the task, our divers have the skillset to accomplish it.”

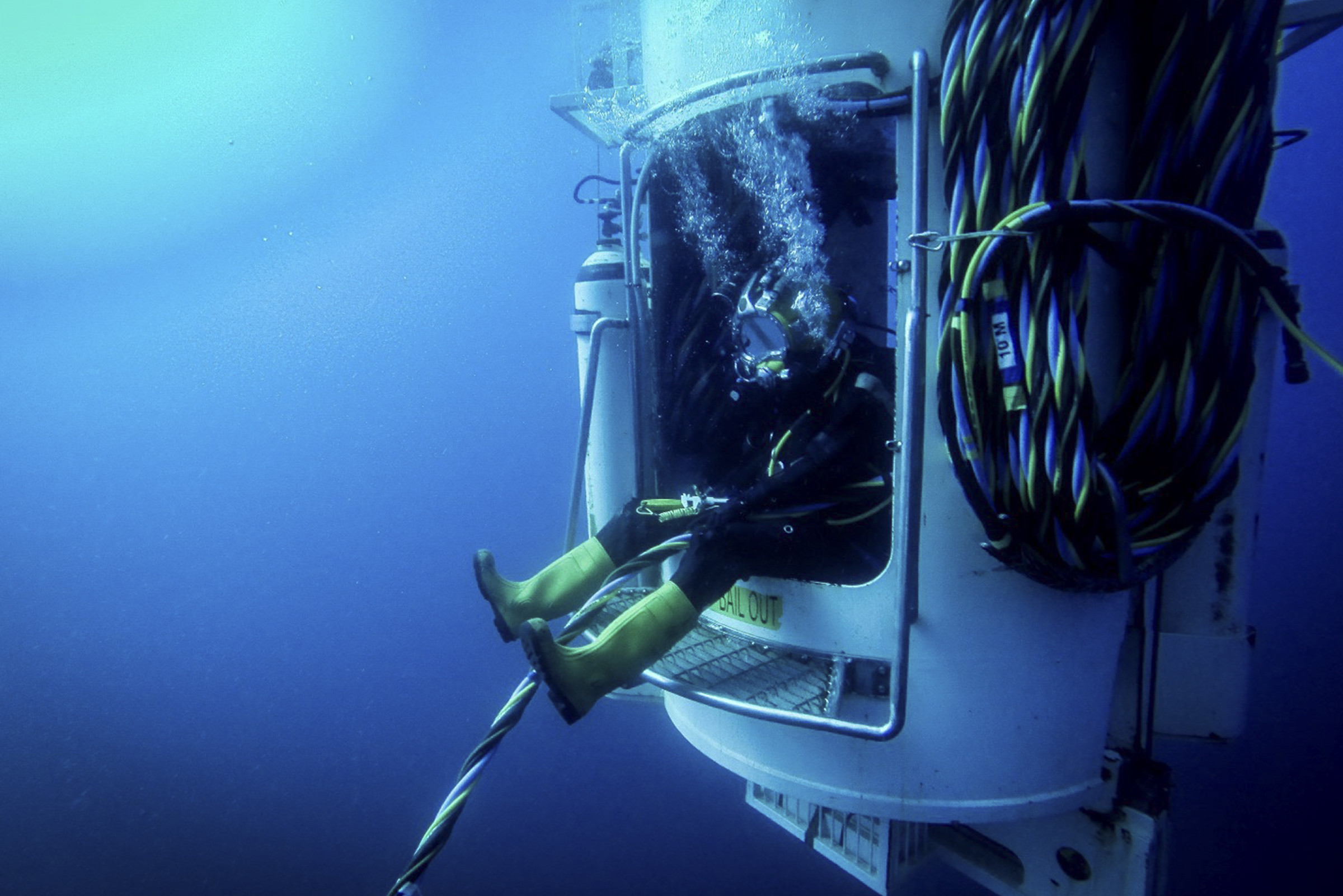

“Our divers work in the toughest conditions at depths of up to 200-300 meters, often at locations where it is almost completely dark and in water temperatures just a few degrees above freezing. Their vision can be limited by sand and other material swept in by underwater currents that clouds the water. They wear purpose-made suits with special cables called umbilicals that supply them with air, hot water, audio, video and light. Obviously our project and engineering managers play a major role in the success of a project, but it is ultimately the divers who execute the works under pressure. It is a challenging and important task. A commercial diver does not work alone and requires the support and assistance of other divers and very often specialist personnel such as supervisors, technicians, life support crew and tenders. Each of these positions is an integral part of the diving team. The support team on board the vessel is responsible for creating safe working conditions both above and below the surface. We abide by the very highest safety standards as set out in our industry and in our safety program NINA (No Injuries No Accidents), which has a very good reputation amongst our clients.”

What can you tell us about the diving systems on board of the DSVs?

“The SAT diving systems are fully integrated within the ship’s hull and systems. They consist of the diving bell, either one or two, a winch system with lift umbicial to take the diving bell to the required depth and provide the divers with their air supply and communications, and compression chambers where the divers live in between their ‘bell runs’. The air pressure in these compartments can be adjusted to the pressure at the depth at which the divers are working. A SAT system furthermore consists of a dive control center, a facility to supply and reclaim the breathing gasses of the divers, and a life support control system to monitor the divers 24/7.”

Mission control

Overall, how many people on board of the large DSVs are involved in a diving operation?

“You could compare the on-board diving system best to a space mission control center. Just as NASA supports its astronauts, we work around the clock to support a team of divers in the safe and efficient execution of their work. We too have a mission control center and life support teams. On our DSVs a large team of around one hundred people is constantly engaged in enabling one or two divers to do their work, from providing fresh food to the divers to keeping the vessel steady at its position from the bridge.”

What kind of tasks do all those on-board workers have?

“The SAT operation is led by the offshore construction manager, who is assisted by a team of supervisors, life support and dive technicians, and project engineers. A six man life support team is responsible for maintaining the right conditions in the compression chambers, regulating things like temperature and air supply. A team of supervisors assists and manages the divers during every step of their work at the seabed. The dive technicians make sure the dive system is being maintained according to regulations and control the handling of the bell. In addition there is the marine crew of the vessel, which is around thirty strong, including the captain, the dynamic position officers and the chief engineers. The marine crew also see to it that the vessel can do its work and that everyone on board gets meals and a clean bed. Because the work goes on 24/7 they also work in day and night shifts. Furthermore there is a doctor (medic) onboard for medical support and teams for the ROVs. We have representatives of the client on board to monitor the work and during inspection works we sometimes also have representatives of certification bodies to witness the proceedings. All this means that it takes a large vessel with sufficient facilities to accommodate everyone.”

Safety before comfort

What is life like for the divers on board of a DSV?

“The divers spend a maximum of 28 days in the interconnected chambers of the SAT system onboard including several decompression days to gradually and safely get back to atmospheric pressure. SAT teams usually consist of nine to twelve divers who work around the clock in three or four shifts. There are always three divers at work at any one time on the seabed. One ‘bellman’ remains in the diving bell to support the two other divers who perform the actual work outside the diving bell. After a six to eight-hour shift they are relieved by the next three divers and rest for the next day. The compression chambers are simply furnished, with the systems being aimed at safety rather than comfort. There are sleeping quarters with three beds on top of each other and a section which has a small dining area with a TV, as well as a shower and a toilet, and of course WiFi. The divers need to be able to eat and drink and change their clothes, and they need rest and relaxation. The food on board is prepared by the ship’s cooks and delivered to the divers via an air lock, bearing in mind the difference in pressure. The same applies to things like clothing, medicines and books. Even the flushing of the toilet is externally controlled from the life support team by means of a special pressure system.”

Extensive range of services

What kind of work do you do most?

“We have a very diverse range of services. A lot of the work is IRM work: inspection, repair and maintenance of complex subsea oil and gas installations, offshore platforms and – increasingly – wind farms. Because our clients have to meet the highest classification standards they hire us to conduct various inspections, such as checking the wall thickness of pipelines, checking welds for cracks and performing other tests. For us these are regular, contractually agreed tasks that recur every year or every other year. In addition our work comprises for example installing or removing subsea infrastructures, such as pipelines, control modules, and subsea umbilicals, risers and flowlines (SURF). The installation work involves installing various kinds of pipes or connectors at varying depths. This might involve fastening or loosening hundreds of clamps, nuts and bolts, and connecting a variety of complex parts. We have the great advantage of having access to all the required disciplines within our company for our projects. Boskalis does not only have a wide range of equipment but also numerous experts in different fields. We have the in-house capability to develop a total solution for both installation and decommissioning projects.”

ROVs

How many ROVs are there on board of the DSVs?

“Depending on the kind of project we use large (work class) and small (inspection class) ROV systems to support our diving operations. The inspection class ROVs are used on almost every job. They act as an extra pair of eyes to monitor what the divers are seeing and they are around the divers to help them with minor tasks. We use ROVs on many offshore projects, including wind farm installations, for example to check the seabed on unexploded ordnance, to follow the power cable touchdown during installation work or to carry out repairs. The work class ROVs come along on board on projects where we have to work at depths greater than the maximum depth of around 300 meters that divers can work at. The work class ROVs are equipped with gripper arms, known as manipulators, which can perform tasks such as repairing a pipeline or closing a valve. The ROVs are operated from the vessel by a team of between four and six pilots/technicians who maintain contact with the dive control team. From a control center the ROV pilot can carry out operations with great precision using monitors displaying camera images from the ROV and using depth gauges and sonar images of the underwater area.”

Unforeseen tasks

Do you also have to perform unforeseen tasks? For example do you attend in emergency situations?

“Definitely, we are called for example if there is a sudden leakage or pressure drop in a pipeline somewhere or in the event of other urgent problems. In cases like these, in consultation with the client, we mobilize our divers or ROVs to carry out first line inspections. Sometimes we do so in collaboration with our colleagues of SMIT Salvage, so in cases like these we can also rely on the broad range of services provided by the business units of Boskalis. The same applies to our decommissioning projects: Boskalis is one of the few companies that offers a full range of services in this area, from the subsea disconnection of a platform with our DSVs to lifting the platform sections out of the water and transporting them to shore with one of our heavy lift vessels. We can tow out an FPSO (Floating Production Storage and Offloading vessel) to its location, install the anchor pattern with our Anchor Handling Tugs and connect the risers between the seabed and the FPSO with our DSVs.

Furthermore, we are also ad-hoc contracted to carry out so-called free span corrections. This involves applying reinforcement under pipelines where the current has washed away the seabed. To prevent the pipeline from being overstressed our divers install new support points using rocks or inflatable bags which are positioned underneath the pipeline and then pumped full of grout (underwater cement) from the vessel. By collaborating with Boskalis’ rock installation specialists we are able to perform rock placement work, for example to protect pipelines on the seabed.

In addition, we have our ports and downstream operations who perform air diving operations to carry out maintenance on harbor quay walls and who can perform underwater repairs on thrusters or propellers of vessels. This is more cost-effective for the client than having a vessel repaired in a dry dock. As such we can offer our clients a truly full range of subsea services.”