When the Dan Bravo Complex offshore Denmark came on stream in 1972 it was expected to produce for 25 years. Now, thanks to a multi-year subsea structural reinforcement campaign, the life of the wellhead platform is expected to more than double.

Jakob Knudsen, DABRAT Project Manager at Maersk Oil and Bert Kamsteeg, Boskalis Contract Manager outline the campaign, which involved the installation of 136 tons of new steel and more than 200 diving days.

What was an important aspect for the success of the Dan Bravo Rationalization (DABRAT) project?

Jakob: “The planning and preparation was key. We did as much as we could onshore. Once you go offshore there’s a high cost involved — every minute costs a lot of dollars. The project was executed in close collaboration with the Subsea Services business unit of Boskalis, which set up an office in Esbjerg for the project. At least one face-to-face meeting was held each day. We have had more than 200 diving days over the last two years. The project couldn’t have been done without this close working relationship.”

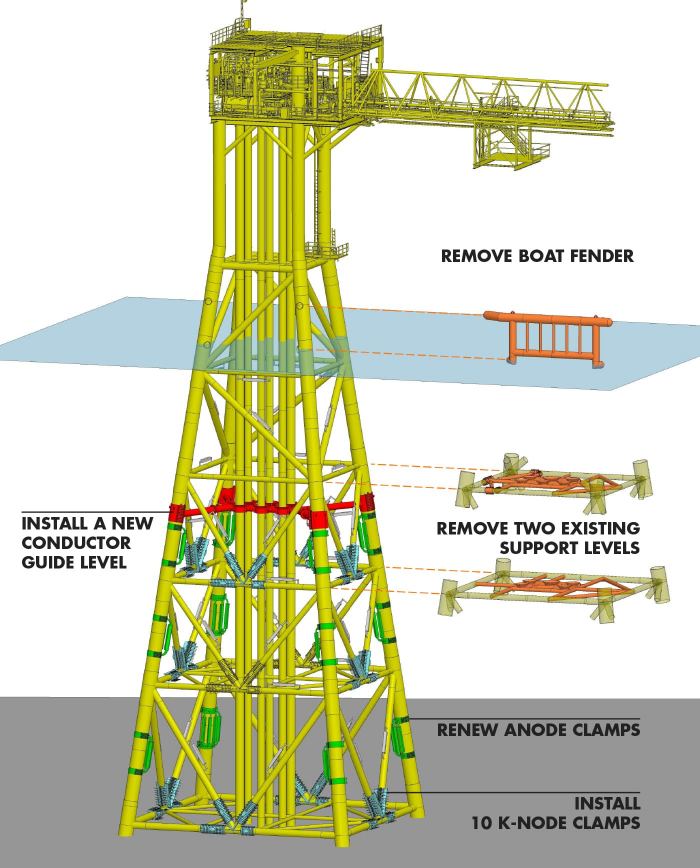

Artist’s impression of the DAN A platform jacket

What role did Boskalis play?

Bert: “Boskalis’ involvement in DABRAT started with preparations in early 2013. Dan A is a wellhead platform and Dan B is the process platform of the Dan Bravo Complex. The main scope was to reinforce Dan A’s jacket, using so-called 10 K-node clamps and to install a new conductor guide level — both of which would require carefully maneuvering 15 pieces of up to 4-5 ton sections of fabricated steel through slots in the platform’s structure.“

“Boskalis Subsea Services was contracted for the installation, fabrication, procurement, equipment testing and structural examinations. It was also tasked with installing a new boat landing ladder on Dan B, as well as removing obsolete equipment from Dan A and B.

Over the 200-day offshore campaign, there were no lost time incidents.

Bert, can you outline how DABRAT was executed given that the platform had to remain in production?

“The project, akin to a 3D, subsea puzzle, involved a large subsea photogrammetry campaign, site cleanup, preparation work and the installation of temporary cranes on vertical platform members to help maneuver the new steel sections into place at a 10-41 meter water depth — all while the platform was in production. Reinforcing platforms in this way and on this scale has never been done before.”

What were the major challenges to overcome?

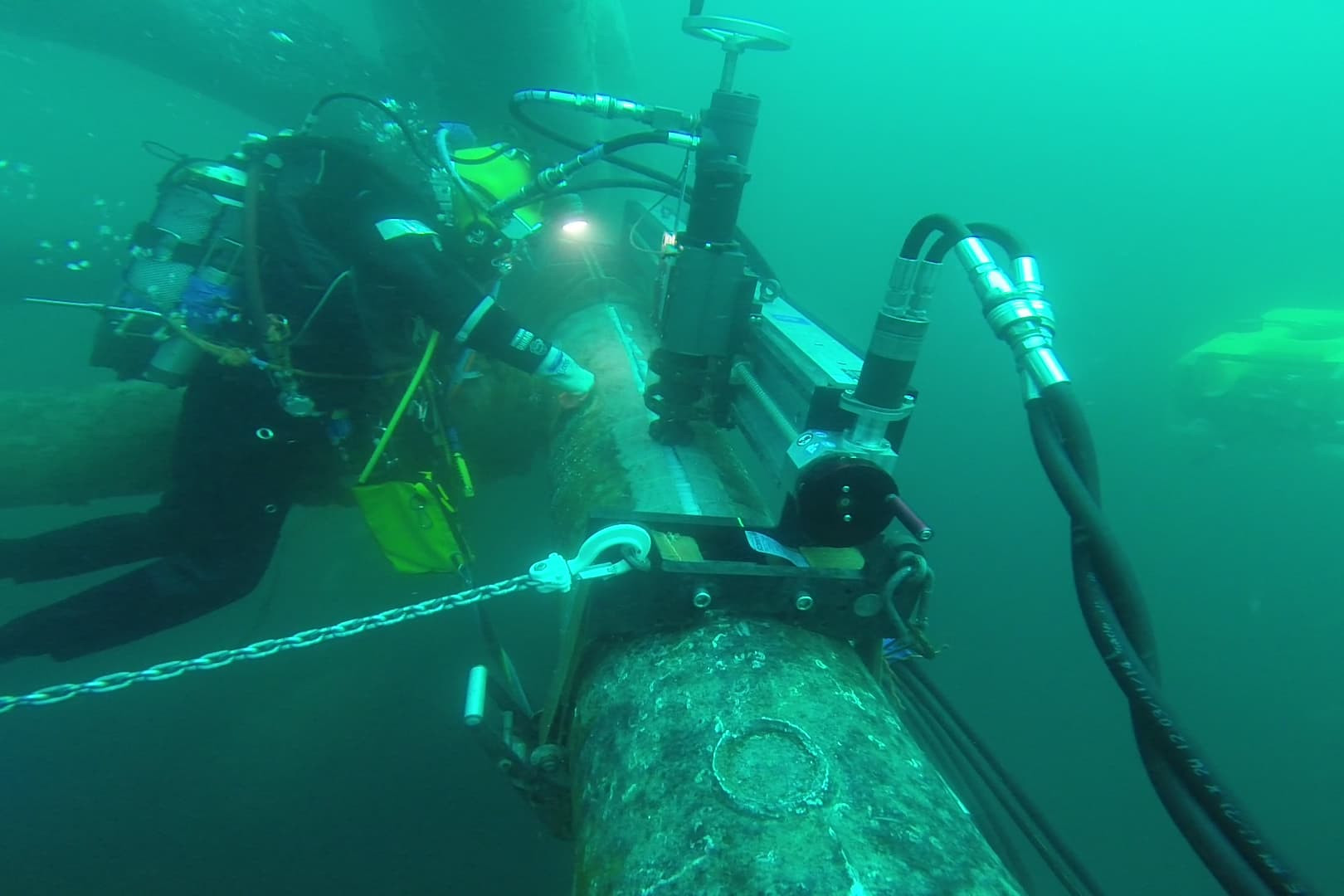

Bert: “The first was mapping the existing structure. From July to September 2013, a huge photogrammetry exercise – the largest ever of its type – was carried out beneath the waves. Subsea, our air and saturation divers first marked out the structure, using 3,000 magnetic, coded markers. Then some 20,000 high-definition, overlapping photographs were taken over a 70-day campaign. The photographs were then converted into an exact geometric 3D-model, using the information from the markers, from which the K-nodes and conductor level guide could be designed.”

“Next, inspection work, surface cleaning and preparation work had to be carried out, all while having to contend with some unfavorable weather conditions and sometimes reduced subsea visibility. Furthermore, divers do not do this kind of work very often. Many risk assessment studies and a lot of trainings were conducted.”

Transferring the steel from the ship to the position beneath the platform was a particular challenge, is that right?

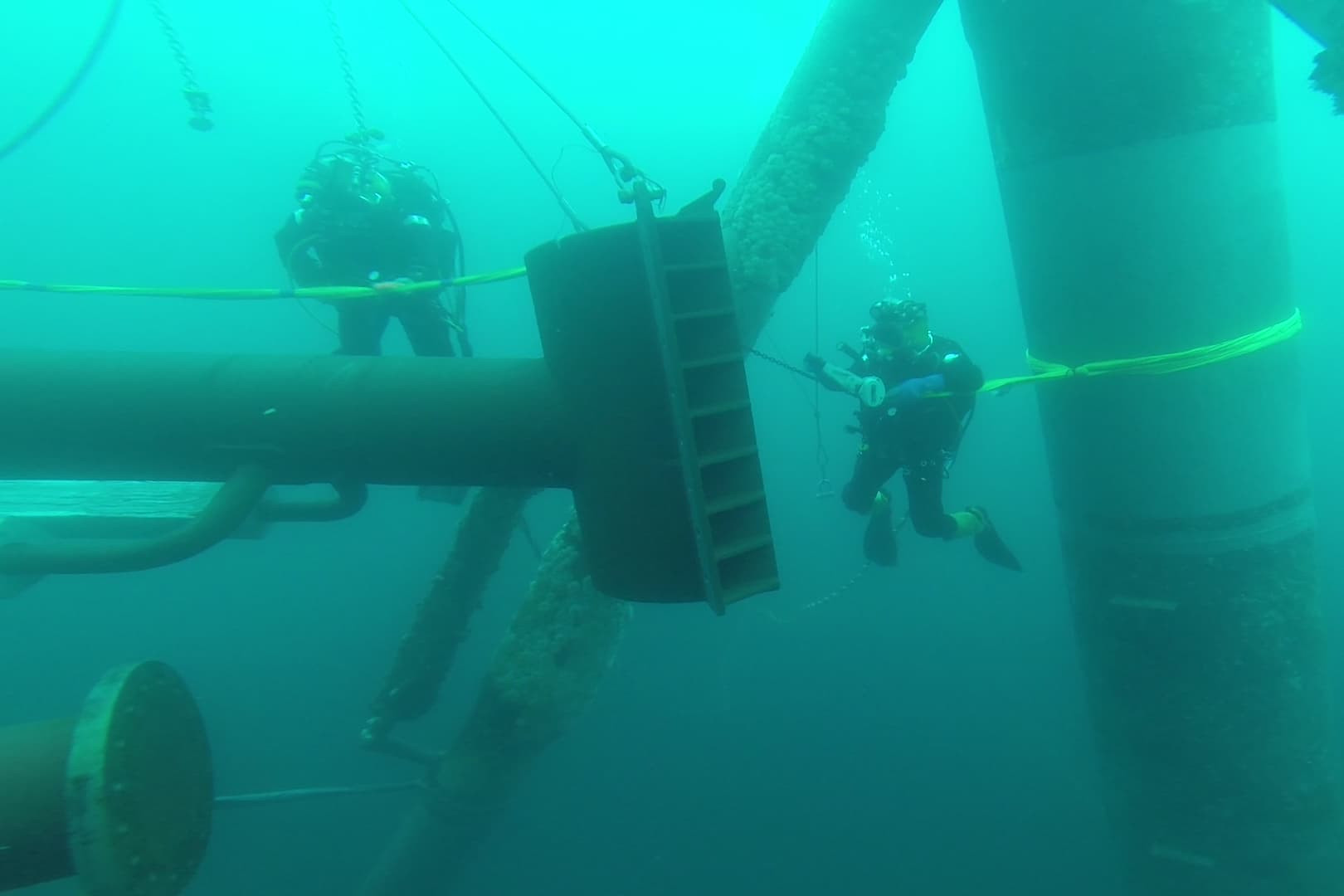

Bert: “The platform had a small 2.3-ton capacity crane but in subsea conditions in some cases the steel sections weighed 4-5 tons. The only sensible solution was to build two temporary cranes, 12 meters above sea level onto the vertical members of the platform. This itself was a challenge, first having to install a clamp with a pedestal on to the vertical member, and then building up a conventional knuckle boom crane onto it — which first had to be dismantled into 2-3 ton pieces in order for the platform crane to be able to lift them.”

“Two cranes which Boskalis already had on its fleet were modified so they could be remotely controlled from the diving support vessel (DSV) to avoid having to procure new cranes and face possible delays.”

“Installing the temporary cranes meant steel could be lowered from one of the two DSVs then connected to the temporary platform crane’s hoist wire, before being disconnected from the DSV’s hook by divers and maneuvered into place, assisted by divers and rope access personnel on the platform.”

And special clamps were designed?

Bert: “The K-clamps were created to reinforce areas of the jacket structure where a horizontal member is intersected by cross members. Each clamp comprised two sections to create a steel-to-steel friction clamp, which are connected using steel bolts weighing 10 kilos apiece. To install the 10 clamps and the conductor guide level, 1,888 bolts were used, each having to be handled and set by the divers using specially built hydraulic tensioning gear and a specially designed tool basket.”

“To install the new conductor guide level, the main section — measuring 3 meters wide and 8 meters long — needed to be lowered, tilted, and slotted through the platform members. The new conductor guide level was bolted into place using further sections of steel.”

This of course was all happening subsea. How vital was communication?

Bert: “Indeed, this was all happening at about 13 meters below the surface, with more than a dozen ‘handshakes’. Coordination above and below the waterline between divers, rope-access workers and the dive supervisor, whose only visual link to what was happening in the water was via a camera on the diver’s helmet and video from observation class remotely operated vehicles, was crucial.

DABRAT really highlights the expertise of the divers doesn’t it?

Bert: “For our divers, this was the most challenging part of the project, due to the volumes of steel involved. Getting the steel sections into position was also the most time-consuming part. We knew we had to get it in position between the six existing conductors. We had to fly it in vertically between the two rows of conductors, then flip it horizontally and fit the out rigging. Then we had to lift it into place, fixate the bellmouths to the conductors and bolt it down. It had to be built up from all the pieces of steel to get it into place and in its proper shape, so it would support the platform itself.”

“Everybody had to wait for the other to be in position or ready. We had two divers, who needed to be in the right position at the right time and they needed the right tools at the right time. In our contingency plan we expected to do it in two weather windows. We actually did it in one!”

“Boskalis also replaced a number of anode bracelets. The final part of the offshore campaign was to remove the temporary cranes before the winter season.”

Looking back at the campaign, it was clearly a success in terms of a huge lifetime extension but also when it comes to HSE?

Bert: “Over the 200-day offshore campaign, there were no lost time incidents, a testament to onshore planning, preparation and onshore rehearsal of many of the steps that were to be undertaken offshore.”

This project will deliver some amazing results in terms of the life extension of the wellhead platform?

Jakob: “In 1972, the facility was Denmark’s first producing offshore oil field and was only expected to produce for 25 years. But DABRAT means that the life of the complex’s wellhead platform, Dan A, is expected to more than double to 70 years!”